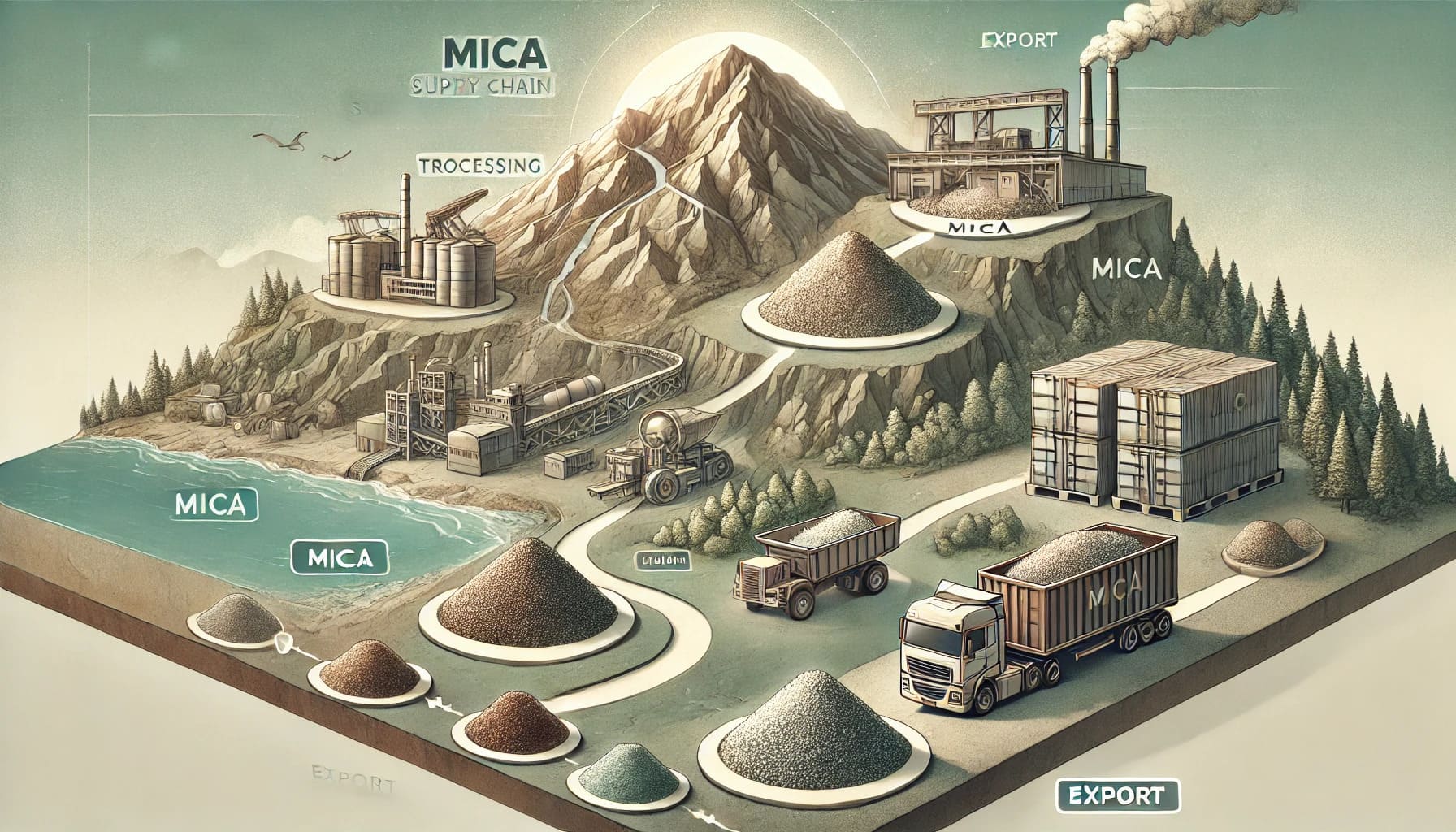

The global demand for mica, a shimmering mineral used across various industries, has significantly increased in recent years. Known for its natural luster and resistance to heat, mica is a popular component in beauty products, electronics, automotive parts, and construction materials. However, few consumers are aware of the intricate supply chain involved in transforming raw mica from mines into finished goods available worldwide. India, particularly, plays a major role in this supply chain, as it is one of the largest exporters of mica globally. Understanding the journey of mica from its extraction to export can shed light on the industry’s challenges and opportunities for ethical and efficient sourcing.

The Mining Process: Where it Begins

The mica supply chain starts with mining, predominantly located in India’s states of Jharkhand, Bihar, and Andhra Pradesh. Mica mining can be done in two ways: open-pit or underground. Open-pit mining, generally more environmentally disruptive, involves stripping large surfaces to reveal mica deposits. In contrast, underground mining, though less invasive, presents challenges in terms of safety and extraction efficiency.

Once extracted, mica is sorted based on quality. High-quality mica is reserved for use in the cosmetics and electronics industries, where purity and consistency are essential. Lower-quality mica, often called “scrap mica,” is typically used in construction or as a filler in various materials.

Processing: Transforming Raw Mica into Usable Material

Once mined, mica undergoes several stages of processing to transform it into usable forms. Here’s a look at each step:

- Sorting and Grading:

Workers manually sort raw mica by quality, removing impurities like dirt or stone. This stage is labor-intensive and often conducted in local processing centers near mining sites. - Cutting and Splitting:

Large sheets of mica are cut or split into thin layers, depending on their intended use. Mica’s unique structure allows it to be split into thin layers without losing strength, which is essential in electronics and heat insulation applications. - Grinding and Pulverizing:

Lower-grade mica is ground into powders used in various industries, such as construction, cosmetics, and automotive manufacturing. Mica powders can be ground to different fineness levels, with finer powders used for cosmetics and coarser ones for construction materials. - Packaging and Labeling:

After processing, mica products are packaged and labeled for export, with specific details based on the target industry and destination requirements.

Exporting Mica: A Key Step for Global Reach

India is a major mica exporter, with countries like the United States, China, Japan, and Europe being prominent importers. The export process involves additional quality checks to ensure the mica meets the standards of each importing country. Documentation, including certificates of origin and regulatory compliance, are essential for international shipping.

One challenge exporters face is the fluctuating demand and price of mica, influenced by global economic conditions and changes in industry needs. For example, an increase in demand for electronics or cosmetics drives up mica demand, benefiting exporters but straining the supply chain.

Ethical Concerns and the Push for Responsible Mica Sourcing

Mica mining has been linked to various ethical concerns, particularly regarding child labor and unsafe working conditions in unregulated mining areas. Reports have highlighted that in regions where formal employment opportunities are limited, children are often engaged in mica collection, working long hours in hazardous conditions. This has led to a global movement for responsible sourcing in the mica supply chain.

The Responsible Mica Initiative (RMI) and other similar organizations work with local governments, companies, and NGOs to improve transparency and accountability within the supply chain. The goal is to eliminate child labor, promote fair wages, and ensure safe working conditions for all involved in mica production.

To meet consumer demands for ethical products, many companies have started requiring suppliers to verify the source of their mica. This transparency builds trust with consumers and encourages brands to engage in more sustainable sourcing practices.

Technology’s Role in Streamlining the Mica Supply Chain

Digital tools and technological advancements are transforming the mica supply chain, enabling more transparency, efficiency, and safety. Some of the innovations include:

- Blockchain Technology:

Blockchain allows companies to track mica’s journey from mine to market, ensuring transparency and traceability. This level of detail assures consumers that products are ethically sourced. - Automated Quality Control Systems:

Advanced machines can analyze mica for quality, reducing the need for manual sorting and improving accuracy. - Sustainable Mining Technology:

New extraction technologies are being developed to minimize environmental impact, reduce waste, and make mining operations more sustainable.

The Future of Mica in Global Markets

As industries continue to grow, the demand for mica is unlikely to slow down. Companies that adopt responsible and transparent sourcing practices will likely lead the way in the global mica market, appealing to consumers who prioritize ethics and sustainability. Increased awareness around mica’s supply chain challenges is driving industry-wide changes, pushing towards a more ethical, traceable, and eco-friendly approach.

By understanding the mica supply chain from mining to export, consumers and industries alike can make informed choices, supporting suppliers who prioritize ethical sourcing. The path forward for mica is bright, promising not just a lustrous shimmer in products but also a more sustainable and ethical future.