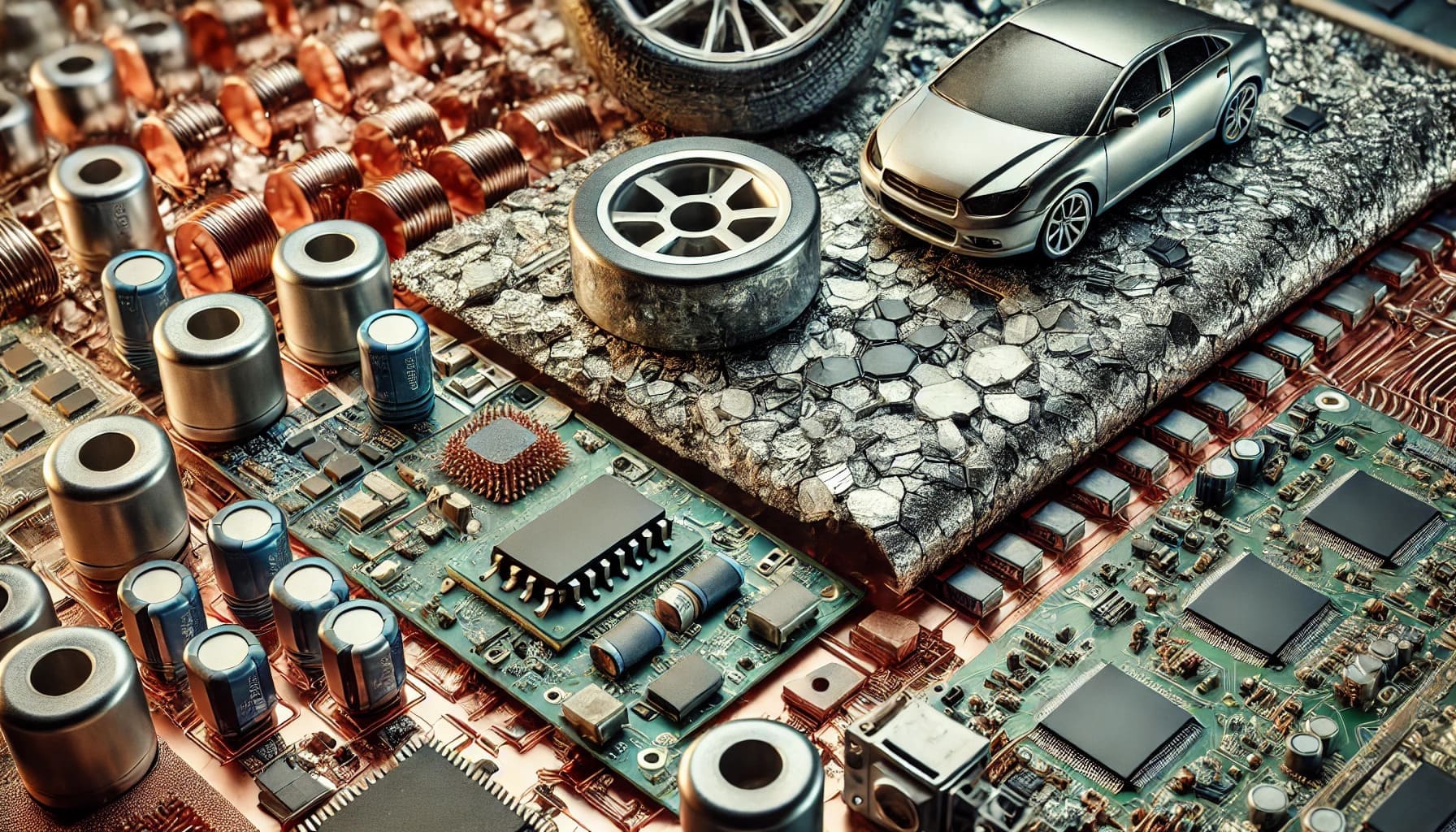

Mica, a naturally occurring mineral known for its thermal resistance, electrical insulation, and impressive stability, has become an essential component in the electronics and automotive industries. This versatile mineral is used in products ranging from semiconductors and circuit boards to automotive heat shields, making it invaluable in an era focused on efficient, durable, and sustainable technology. In this blog, we’ll explore how mica contributes to these industries, its unique properties, and how it supports innovations in electronics and automotive engineering.

Mica in the Electronics Industry: Enhancing Performance and Reliability

In the electronics industry, mica is valued for its dielectric strength and heat resistance. These properties make it ideal for insulating electronic components, allowing devices to operate at high voltages without overheating or short-circuiting. Here are some primary applications of mica in electronics:

- Capacitors and Insulators

Mica capacitors are widely used in high-frequency circuits, where stability and precision are critical. Mica provides an insulating layer that maintains high performance and reliability, making it suitable for components like radios, oscillators, and filters. Additionally, mica sheets and tapes are used as insulators in various electronic devices due to their resistance to high temperatures. - Semiconductors

Mica’s thermal stability is essential in semiconductor manufacturing, where it acts as a substrate or base for silicon wafers. In this application, mica’s smooth surface, thermal resistance, and high insulation properties allow semiconductors to function efficiently and withstand temperature fluctuations, which are common in high-power electronic devices. - Heaters and Circuit Boards

Thin sheets of mica are frequently used as insulators in heating elements and printed circuit boards (PCBs). The mineral’s high heat resistance ensures that circuits and heaters can operate under intense conditions, enabling longevity and stable performance in electronic appliances and industrial applications.

Mica in the Automotive Industry: Durability and Thermal Efficiency

The automotive industry, like electronics, benefits immensely from mica’s properties, particularly in terms of thermal management and durability. Here’s how mica is utilized in automotive manufacturing:

- Heat Shields and Gaskets

One of the most common uses of mica in the automotive industry is in heat shields and gaskets. These components protect various parts of the engine and exhaust system from excessive heat. Mica-based shields can withstand high temperatures, preventing heat transfer to sensitive components and reducing the risk of thermal damage. - Battery Insulation in Electric Vehicles

As electric vehicles (EVs) become increasingly popular, the demand for materials that can insulate and protect batteries from overheating has grown. Mica’s thermal stability makes it ideal for battery insulation, helping manage the heat generated during EV operation and enhancing battery life and safety. - Brake Pads and Clutches

Mica is often incorporated into brake pads and clutches due to its friction-resistant properties. By withstanding intense friction and high temperatures, mica-based brake pads offer improved braking performance and increased durability, making them ideal for modern vehicles, especially those that are performance-oriented.

The Advantages of Mica: Why It’s Indispensable in Electronics and Automotive Applications

Mica’s unique characteristics make it the material of choice for engineers in both industries. Here’s why mica stands out:

- Thermal Stability: Mica can withstand temperatures up to 1,000°C, which is crucial in applications requiring heat resistance, such as automotive engines and electronic circuit boards.

- Electrical Insulation: With high dielectric strength, mica provides excellent electrical insulation, making it suitable for components operating at high voltages.

- Durability: Mica’s layered structure allows it to endure physical stress without breaking down, essential for automotive and electronic components exposed to harsh conditions.

- Lightweight: Despite its durability, mica is lightweight, which contributes to overall efficiency, particularly in vehicles where weight reduction improves fuel efficiency and battery life.

Emerging Trends: Mica’s Role in Sustainable and Advanced Technologies

As the automotive and electronics industries increasingly focus on sustainability and innovation, mica’s role is evolving to support new technologies:

- Mica in Sustainable Electronics

The demand for sustainable electronic devices has created interest in mica’s natural, eco-friendly qualities. Unlike synthetic insulators, mica is biodegradable and doesn’t release harmful chemicals when disposed of, aligning with environmentally responsible production standards. - Advanced Battery Technologies

Mica’s role in EV battery insulation is expected to expand with the growing emphasis on electric mobility. Manufacturers are exploring ways to integrate mica-based materials into next-generation batteries, making EVs safer and more efficient. - Wearable Electronics

Mica’s lightweight, heat-resistant qualities make it a promising material in the development of wearable electronics, where components need to endure body heat and environmental exposure without compromising performance.

The Future of Mica in Electronics and Automotive Industries

Looking ahead, mica is set to remain a key material in electronics and automotive applications, supporting the push toward greener, safer, and more efficient technologies. Innovations in mica processing and product integration are opening up new possibilities, from enhancing EV battery systems to improving the performance and sustainability of electronic devices.

As industries move toward eco-friendly and resilient solutions, mica’s role is likely to expand, benefiting manufacturers and consumers alike. The enduring reliability and versatility of this mineral underscore its importance in driving progress across technology sectors, ensuring that devices and vehicles can keep pace with our evolving needs.

In conclusion, mica’s applications in the electronics and automotive industries highlight its indispensable qualities and potential for growth. Whether insulating a high-performance circuit or enhancing the efficiency of electric vehicle batteries, mica is truly a material that bridges traditional and modern technology, offering solutions that are as resilient as they are forward-thinking.